NWT Sports Professional World Athletics Certificate Prefabricated Rubber Running Track

Prefabricated Rubber Running Track Features

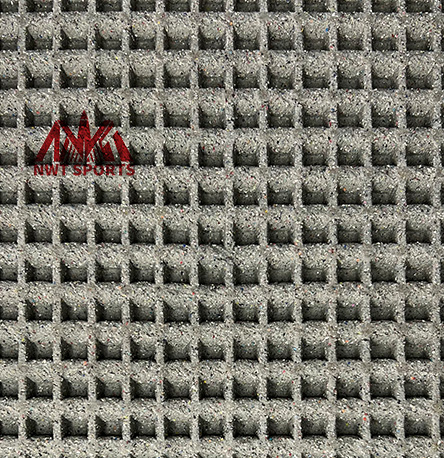

Our rubber running track has better performance on aging resistance and shock absorption because we choose better material and advanced technology. In the design process of the product, the biomechanical needs of the athletes have been fully considered: The three- dimensional net-like internal structure makes the runway have excellent elasticity, strength, toughness, and shock absorption effect and effectively reduces the athlete's muscle fatigue and micro-injury.

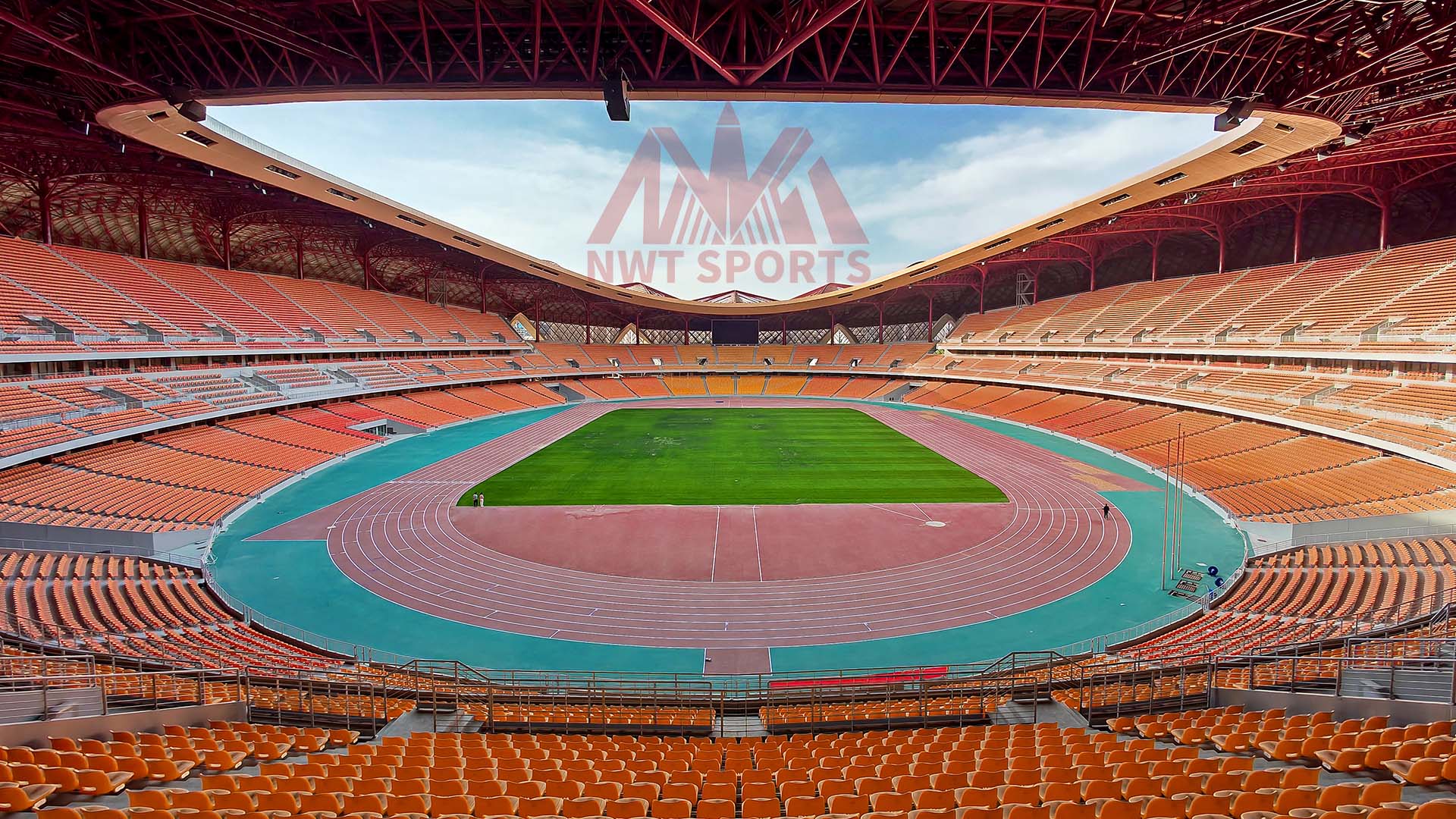

Prefabricated Rubber Running Track Application

Prefabricated Rubber Running Track Parameters

| Specifications | Size |

| Length | 19 meter |

| Width | 1.22-1.27 meter |

| Thickness | 8 mm - 20 mm |

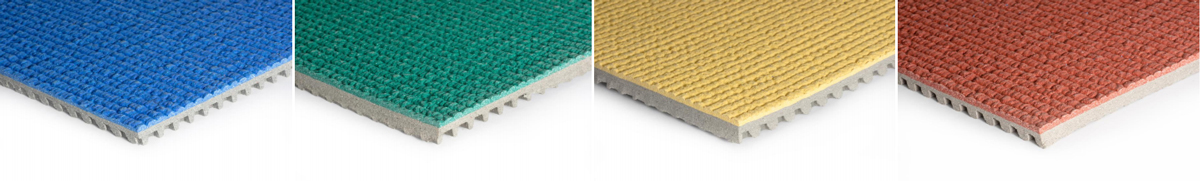

| Color: Please refer to the color card. Special color also negotiable. | |

Prefabricated Rubber Running Track Color Card

Prefabricated Rubber Running Track Structures

Our product is suitable for higher education institutions, sports training centers, and similar venues. The key differentiator from 'Training Series' lies in its lower layer design, which features a grid structure, offering a balanced degree of softness and firmness. The lower layer is designed as a honeycomb structure, which maximizes the degree of anchoring and compaction between the track material and the base surface while transmitting the rebound force generated at the moment of impact to the athletes, thereby effectively reducing the impact received during exercise, and This is transformed into forwarding kinetic energy, which improves the athlete's experience and performance.This design maximizes the compactness between the track material and the base, efficiently transmitting the rebound force generated during impacts to athletes, converting it into forward kinetic energy. This effectively reduces the impact on joints during exercise, minimizes athlete injuries, and enhances both training experiences and competitive performance.

Prefabricated Rubber Running Track Details

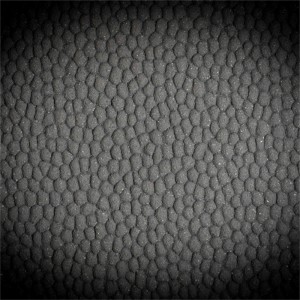

Wear-resistant layer

Thickness: 4mm ±1mm

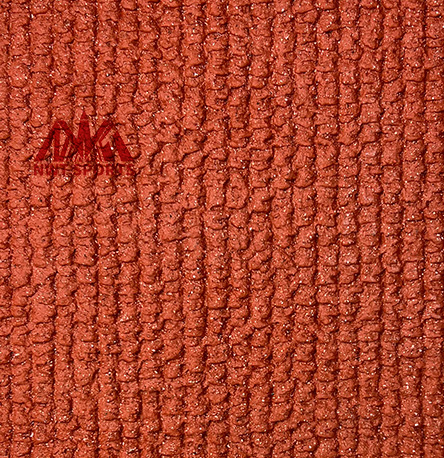

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation